Asphalt has historically been used for multi-storey car park waterproofing and surfacing. It is commonly found where car park decks are exposed or where internal decks are over occupied premises. Here, we consider the issues that car park owners and operators face as these structures age and the asphalt deteriorates.

We discuss the choices for asphalt repair, asphalt strip up and replacement, as well as a technologically advanced asphalt overlay solution to provide car park waterproofing, surfacing and protection.

Multi-storey car parks need structural protection

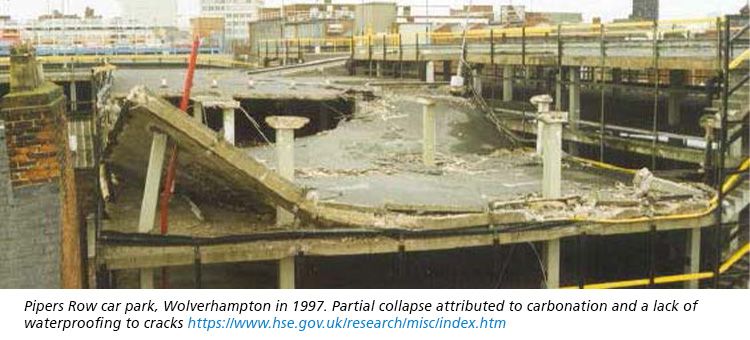

Protecting reinforced concrete car park structures is essential to prevent structural damage and structural failure. In reinforced concrete, the alkaline concrete itself provides protection to the steel reinforcement from corrosion via a passive layer. The primary risk to structural integrity is the corrosion of the steel due to chlorides in road salts or as a result of carbonation.

Chlorides from road salts dissolved in water are driven in and deposited by vehicles. If the concrete structure does not feature fully waterproofed coverings, these dissolved chlorides can migrate to the steel reinforcement, particularly where the concrete is cracked. When chloride ions reach the steel surface, their combination with hydrogen ions contained in the pore water, creates acids which neutralise the alkalinity of the concrete. The result is a breakdown of the passive film layer leading to localised corrosion.

Carbonation is the process of carbon dioxide (CO2) entering the concrete and reacting with hydrated cement paste in pore water. As this is acidic, it reduces the natural alkalinity of concrete. When the carbonation front reaches the steel reinforcement surface, the alkalinity forming the passive layer is neutralised; and in the presence of oxygen and water, corrosion occurs. Carbonation can be prevented using carbon dioxide resistant coatings to the decks and anti-carbonation coatings to the soffits and other elements.

- Chlorides from road salts carried into the structure by vehicles can lead to corrosion

- Carbonation is a threat to unprotected concrete structures

- Carbon dioxide is in the atmosphere and is forecast to increase in future

- Without structural protection, chlorides and carbonation will cause damage leading to structural failure

Asphalted car park decks

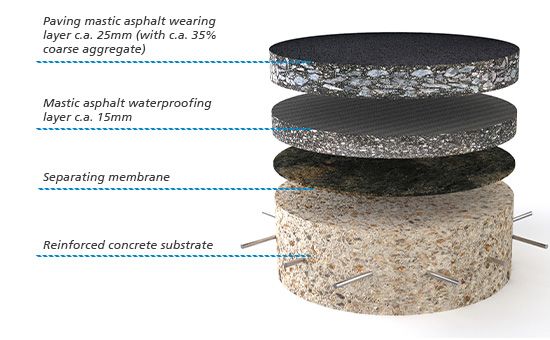

Mastic asphalt, or more simply known as asphalt, has been used as a waterproofing and protection medium for decades. In multi-storey car parks, asphalt build-ups are often found on decks and ramps exposed to the elements or internal decks over occupied premises.

What is the asphalt used on car parks?*

*Typical thicknesses based on thousands of core samples taken from asphalted car park decks by Triflex in the UK.

Mastic asphalt consists of limestone aggregates historically bound together by Trinidad Lake asphalt, but now by bitumen, or polymer modified bitumen. Bitumen (and therefore asphalt) is a thermoplastic which means that it is soft, pliable, and mouldable when hot, and hard when cool.

Mastic asphalt in car parks is applied under extremely high and very strict temperature controls for the best performance. The molten asphalt is laid by hand onto a separating membrane / tissue, with all layers of the build-up applied concurrently to minimise the risk of contamination and critically, moisture between the layers.

In the UK, the types and quality of asphalt encountered vary depending on the age of car park.

3 key drivers for action

Car park owners, operators and facility managers face many challenges as part of their car park life-care planning. In asphalted car parks, there will come a time when the asphalt has deteriorated to such an extent that action needs to be taken. There are three key drivers for action:

Waterproofing failure

- Ingress of chlorides, carbonation and structural damage (corrosion)

- Water ingress and damage to property below

- Damage to vehicles below

- Poor conditions leading to reduced footfall

- Reputational damage for those served by the car park

Loss of structural protection

- Reinforcement corrosion

- Concrete deterioration

- Concrete spalling

- Concrete cracking

- Long term structural damage

Health and safety concerns

- Risk of skidding and slips from water in ponded areas; especially when frozen

- Skid risk and slip hazard with worn, polished asphalt; particularly when wet

- Falling debris e.g. spalling concrete

- Surface trip hazards

9 asphalt failures that you cannot ignore

- Asphalt cracks

- Asphalt details and interfaces

- Blisters in asphalt

- Surface ponding

- Tyre indentations

- Skid risk from worn asphalt

- Slumping

- Asphalt contamination

- Asphalt repairs

What to do with failing asphalt?

Car park owners, operators and facility managers face several choices to address the asphalt problems that pose risks to their structures and those that use them:

- Repair asphalt for a temporary solution

- Completely remove asphalt and replace with new asphalt

- Completely remove asphalt and replace with a liquid applied membrane

- Overlay in situ asphalt with liquid applied PMMA waterproofing

1. Repair asphalt for a temporary solution

Temporary or patch repairs can be appealing financially. However, using asphalt as a repair material for failed asphalt can be problematic. Patch preparation requires cutting an area with vertical sides to ensure a neat edge. The patch repair then requires a staggered joint to maintain waterproofing integrity, ideally with the stagger at the interface between the paving and mastic asphalt layers. Unfortunately, as these layers are fully bonded, creation of this staggered joint is difficult and therefore very rarely undertaken.

Cutting the asphalt releases tension in the existing material which will tend to shrink away from the repair over time. As the new asphalt ages, it will also shrink. Shrinkage of both the old and new materials will place tension on the perimeter of the repair. As both sides of the repair pull away from each other it is common to see cracking around asphalt repairs in asphalt. Any full system cracking around the repair will allow water and chloride ingress as well as a path for carbonation. Subsequent freeze thaw cycles will further increase the width of the cracks.

Using hot asphalt for car park repairs requires zones to close to allow access for machinery and ensure the safety of car park users. Opening the surface for patch repair also introduces a risk of water ingress during the works, with a period of dry weather required. Cold mix asphalts may be suitable for short term emergency patches to mitigate health and safety risks but only offer a limited solution as they will not reinstate the waterproofing.

Issues with asphalt as a repair material:

- Staggered joints are required for waterproofing integrity

- Staggered joints are difficult and time-consuming to form

- Asphalt shrinkage of old and new materials often causes cracks to the perimeter of repairs

- Hot asphalt repairs require specialist installers and closures due to hot works

- Due to mobilisation costs, small scale repairs are not economical

- Failures at details are difficult to successfully repair with asphalt

- Cold mix asphalt repairs are only temporary, will typically fail quickly and are not waterproof

- The repairs will be subject to the same failure mechanisms as the original asphalt

- The failure of the waterproofing because of the repair may be worse than the original failure being treated

2. Completely remove asphalt and replace with new asphalt

The removal of asphalt is a major undertaking given the sheer weight and volume of material. Methods of removal are dictated by the site conditions, as well as the size and ease of access for any associated plant machinery for mechanical removal. Great care must be taken to avoid the risk of damage to the substrate by these methods. The broken asphalt is disposed of via chutes, skips or similar means.

Whilst uncontaminated mastic asphalt can be recycled, the fact that the build-up comprises of both mastic and paving asphalt makes this problematic. In practice, asphalt regularly goes to landfill. Extrinsic costs such as site set up, removal costs, transport, the appropriate waste management classification and waste separation procedures all add up. Keeping the car park open is challenging in such a major construction project. In a town centre location this could include pavement closures, town centre access issues, scaffolding, and site security to prevent debris being thrown from the area.

The removal of any waterproofing also introduces significant risks of water ingress. In car parks that are over occupied spaces, there are added risks. If the substrate beneath the asphalt contains lightweight insulating concrete (Lytag or similar), it is highly likely that the removal process will cause some damage to the substrate. Any such damage will require repair prior to asphalt reinstatement. As the voids within the material act like a sponge if subjected to water, the impact of any water ingress during works is significant. Saturated materials are exceptionally difficult to de-water or dry out sufficiently to allow new asphalt installation.

Issues with completely removing asphalt and replacing with asphalt:

- Disruptive and time-consuming

- The amount of asphalt removed is typically only what can be replaced in the day

- Car park deck closures leading to loss of footfall and revenue

- Significant risk of water ingress during the works

- Issues for new asphalt installation where substrates retain water (lightweight insulating concrete or insulation present)

- High likelihood of surface repairs if lightweight insulating concrete is present

- Higher environmental impact

3. Remove asphalt and replace with liquid applied membrane

There are important considerations to take when removing asphalt. Firstly, the underlying, unseen substrate must be suitable for the liquid membrane and must not be lightweight insulating concrete or an unreinforced screed.

Structural loadings are calculated as part of the engineering design and specification for the car park construction. A typical 40mm asphalt build-up imposes a c.a. 100Kg/m2 load. For a 5,000m2 car park deck, this equates to approximately 500 tonnes.

A replacement liquid applied membrane may only weigh 10% of this, resulting in a very significant reduction in dead load. It is important to consider the impacts of removal of this weight on the structure and seek the advice of a qualified structural engineer. Structures can exhibit elastic recovery or decompression following long term dead load removal. This movement or “springing” can lead to new, unforeseen cracking in the concrete deck and a potential weakening of structural integrity.

Unfortunately, these cracks can take time to form as they may be influenced by the reintroduction of live loads (car movements) to the structure. Removing the asphalt build-up also requires modification or replacement of various details including outlets, joints and thresholds.

Issues with stripping up asphalt and replacing with a liquid applied membrane:

- The works are disruptive

- Closure of car park decks and loss of revenue / footfall

- Significant risks of water ingress during the works

- Full assessment of suitability for a liquid applied membrane not possible until asphalt removed

- The substrate may be damaged in the asphalt removal process

- Deck “spring back” may lead to significant structural cracking

- Replacement or modification of outlets, joints, and thresholds due to a reduction in levels

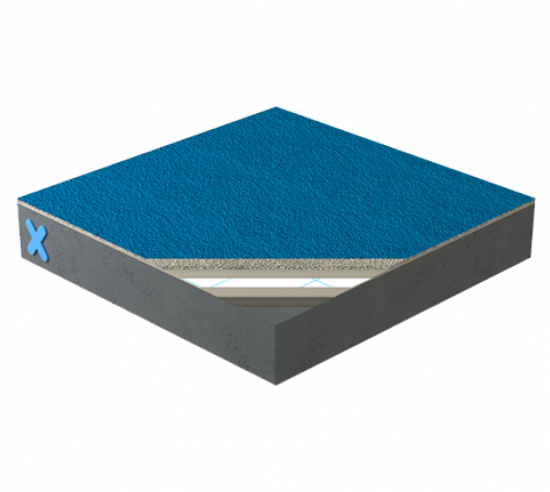

4. Overlay in situ asphalt with liquid applied PMMA waterproofing

Overlaying the existing in situ asphalt with technologically advanced PMMA (Polymethyl Methacrylate) liquid coatings delivers significant advantages. Not only does this deliver minimal disruption but presents a more sustainable option.

By avoiding the need to remove the asphalt, the project moves up the waste hierarchy with solutions that reuse existing materials. Negating the removal and recycling of tonnes of asphalt also shortens the programme of works, minimises disruption and generally avoids full closures.

By overlaying existing asphalt with a proven and compatible system, waterproofing and protection is quickly and simply achieved. Furthermore, with operational disruption reduced, the car park income generation is much less compromised.

Benefits of an asphalt overlay solution:

- Less disruption to car park operation

- No costly or time-consuming strip up

- No waste management for disposal of tonnes of asphalt

- Asphalt defects such as ponding and wheel indentations can be corrected

- Cracks and other failures can be repaired with certified crack bridging materials

- Shortened programme of works

- Avoids risk of altering structural loads

- No risk of water ingress during works

- Heights of outlets, joints, thresholds etc. are maintained

- Greener credentials

Triflex PMMA systems for asphalt overlay

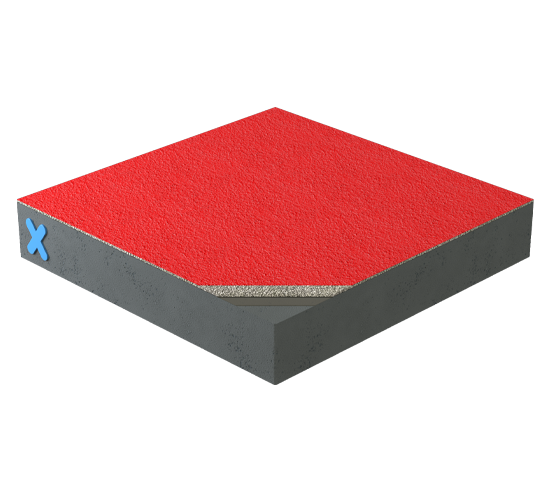

Overlay systems based on Triflex cold PMMA resin technology cure in minutes, even at low temperatures. The technology is also available in Triflex PMMA repair mortars enabling rapid surface repairs and levelling.

Quickly installed, Triflex PMMA overlay solutions are completed rapidly with an efficient programme of works. Consequently, car parks are soon back to full use, minimising interruption to users and revenue generation.

Benefits of PMMA for asphalt overlay and repairs:

- Rapid curing for shorter programmes of works and minimal disruption

- Tough, durable coating with proven longevity for peace of mind

- Can be fully or partially reinforced providing solutions to a wide range of structural protection needs

- Cures in winter temperatures for all year-round project delivery

- Seamless, self-terminating liquid coating for effective, rapid installation

- Elastomeric properties even at low temperatures for year-round protection

- High levels of anti-skid retained over time for a safer environment

- Lightweight material for minimal effects on structural loading and levels

- Outstanding waterproofing properties, including treatment of all existing cracks, details and interfaces for long term structural protection

- Hydrolysis resistant for waterproofing excellence in unresolved ponded water

- Forms strong bond to asphalt and other substrates with proven compatibility

- Thermosetting plastic means lower effects of high temperatures for durability

- Totally cold solution avoiding hot works and associated risks

- Wide range of UV stable colours for individual design aesthetic

- Can be overlaid for future refresh delivering flexible design and branding

Assessing the suitability of in situ asphalt for PMMA overlay

Asphalt build-ups can vary, even within the same structure. Variables such as asphalt temperature, aggregate distribution and external conditions during the installation contribute to differences in the asphalt as laid. It is therefore important to assess the asphalt prior to overlay, in order to provide the appropriate waterproofing and protection solution, as well as identify repair and preparation methods.

The extraction of cores enables an evaluation of the asphalt condition. With often large expanses of asphalt involved, core sampling needs to be extensive and representative of the whole area. It must not only include any obvious defects, but also apparently sound material.

What lies beneath?

Whilst a thorough visual inspection is of value, there is nothing like getting into the build-up to really understand the underlying causes of any failures.

Core sampling shows the condition of the asphalt, thickness of the various layers, size, and distribution of aggregates, as well as any separating membrane. It can also highlight points of concern, such as where large aggregate has sunk below the surface, or the layer thicknesses are less than those expected.

Understanding the innate condition of the existing asphalt build-up ensures the correct solution. On-site services such as core sampling and adhesion testing are a precursor to meaningful warranties backed by insurance for any car park protection system.

By thoroughly characterising the asphalt not only are areas of repair identified, but the level and nature of preparation can be determined to ensure that any bespoke specification proposal meets project requirements.

The paving asphalt layer contains coarse aggregate and should be uniform all the way to the surface. In this example, the large aggregate has sunk leaving a bitumen-rich surface. This may be due to the asphalt being too hot during installation or a lack of large aggregate. This softer, bitumen-rich surface is prone to wheel indentations, displacement, ruckling and accelerated wear.

Why test?

- A visual survey only tells the story at the surface

- Often the build-up is not as it should be

- Assesses the asphalt thickness, layers, stone content and contamination

- Identifies how defects have occurred and how they should be repaired

- Identifies surface preparation requirements

- Allows creation of a bespoke project specification proposal

Triflex products and services: proven asphalt overlay

Triflex waterproofing, surfacing and protection systems have been used to overlay over 2 million m2 of asphalt in the UK alone. Our expertise continues to serve specifiers, car park owners and operators with a range of solutions.

Triflex PMMA repair solutions

Triflex has a range of rapid curing, waterproof, repair materials for asphalt. These materials bond securely to the host asphalt. The Triflex repair materials can move sympathetically with the retained asphalt due to the elastomeric properties of PMMA combined with adhesion in excess of the cohesive strength of the asphalt. In addition, specifically designed reinforced over banding can bridge dynamic cracks and open dayjoints for a robust repair.

Thanks to the rapid curing, repairs can be trafficked within hours minimising disruption.

Triflex PMMA cold liquid applied waterproofing, surfacing and protection systems:

- Over 35 years’ experience directly overlaying asphalt

- 2 million m² of failed asphalt overlaid in the UK alone

- All year round application (temperatures as low as -5°C at details)

- Fully reinforced waterproofing to details

- Fully and partially reinforced systems to main area

- Solvent and isocyanate free

- Rapid curing within hours

- Rainproof in 30-45 minutes

- Quickly trafficable

- Totally cold applied: zero flame

- Hydrolysis resistant: unaffected by ponding water

- Resistant to chlorides (road salts), carbon dioxide ingress, petrol, diesel, brake fluid, engine oil, battery acid, de-icing, and cleaning products

- Tried, tested, and certified to the highest industry standards including BBA, UKCA and EN 1504-2 certified systems

- Proven in the toughest environments in the UK, Europe and beyond

- Can withstand high mechanical loads

- High levels of anti-skid

- Versatile and fully adaptable to your design

- Available in a variety of colours and finishes

- Meaningful warranties backed by insurance

Summary of asphalt overlay

Asphalt can be easily and quickly overlaid with cold applied Triflex PMMA car park waterproofing and protection systems. With over 2 million m2 of asphalt overlaid in the UK to date, Triflex systems deliver proven, outstanding waterproofing, surfacing and protection with chemical and hydrolysis resistance.

With Triflex reinforced systems, movement is accommodated negating risks of cracking and therefore water and chloride ingress, or carbonation. Asphalt overlay avoids the risks of cracking due to structural load changes encountered in asphalt removal, as well as costly waste management of tonnes of removed asphalt. By leaving the existing asphalt in situ, the underlying structure is not exposed to water damage during the programme of works, which can be especially pertinent to areas above occupied spaces.

Detailing, drainage points, upstands and interfaces are all waterproofed without the need for alteration. With quick cure times even at winter temperatures, Triflex solutions offer minimal disruption to car park operation any time of year.

Triflex support services thoroughly assess the asphalt condition. By innately understanding the build-up, we recommend the best solution and preparation, including PMMA based asphalt repair materials that will not delay a challenging programme of works. Our warrantied solutions are backed up by meaningful insurance for peace of mind and installed by our national network of trained and authorised contractors. For a proven, cost effective, sustainable solution that minimises disruption and saves time, Triflex asphalt overlay delivers warrantied waterproofing, protection, and surfacing.